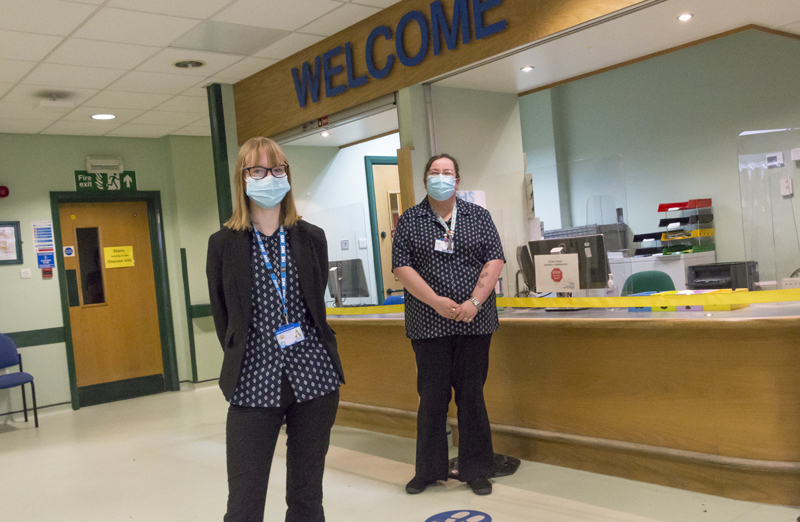

Laura tells what it was like to have a C-section after testing positive for Covid-19, and how she ‘never felt anything other than safe and cared for’

Laura was Covid positive when she came into Hull Women and Children’s Hospital for a Caesarean section just before Christmas. When she got in touch a few days ago to tell us of baby Harry’s safe arrival and how positive her experience had been despite the obvious Covid challenges, this really was music to our ears.

If you’re due to have a baby in the coming days, weeks or months, we hope Laura’s story below will offer you some much needed reassurance in these difficult times.

“I opted to have Harry by elective C section. Monday 14th was the day, and it’s a good job it was because my contractions actually started at 4:30am that morning; he was ready to come that day no matter what!

“I’d been isolating at home since Josh [Laura’s partner] had a positive Covid test around five weeks earlier. We did our standard isolation period, though I had no symptoms and so I never got tested. On the advice of the health care visitor, I decided I would just carry on staying at home until the 14th, apart from attending medical appointments.

“Two days before my C section, I went to hospital for routine tests, one of which was a Covid test. I was a bit apprehensive but was quite sure I wouldn’t have it, based on the fact I’d not left the house for weeks and I had zero symptoms.

“However, the next day the phone rang, with a sympathetic sounding midwife on the phone. She told me I’d tested positive and that meant there was a high chance that my birth partner would not be able to attend the birth.

“Phone down, anxiety through the roof, crying on the phone to Josh in the vegetable aisle of Morrisons and then to mum who I’m sure could barely understand me through the blubbering mess.

“It took me a while to calm down, rationalise, and get a grip. I was lucky to actually feel well still with this virus, and lucky that I could still go to hospital at all and receive medical care. I was determined to see the positives (literally)…

“The next day was “C Day”. Josh and I sat in the car in the hospital car park, waiting to see if the lead midwife and surgeon that day would agree to let Josh in, or would this be it? Then just come back to pick us up tomorrow?

“It was an anxious 50 minute wait as they were dealing with an emergency inside. Then the phone rang: “I’m coming to get you both Laura, your husband is allowed in…”

(Here ensued more crying, obviously…)

“From that moment on, the care I received from all the NHS staff at Hull Women and Children’s Hospital was absolutely amazing. At no point was I made to feel anything other than safe and cared for despite the obvious risks to themselves from dealing with a Covid positive mother.

“The midwife that I had that day was so wonderful and reassuring. She was keeping an eye on us all, answering questions, talking us through the procedure. The surgeon came in and talked us through the surgery, and then the anaesthetist (who had the biggest impact on my day) came to explain the epidural.

“We only waited a few hours in our own separate ‘Covid room’ and then we were wheeled down to a special Covid theatre for our special Covid baby. The main concern from all of the staff was not that they were putting themselves at risk to take care of me and the baby, but that I could understand and hear them through their masks and glasses and that I felt happy and understood what was going on.

“They all wore full respiratory masks for the surgery itself; it was like being operated on in a space ship, and during every step of the surgery each member of staff through their many layers of facial PPE got close enough to look me in the eye and tell me what was about to happen.

“Harry was born at 11:50am, but in another 2020 jab to the ribs, he had problems breathing for the first 20 minutes. They whisked him into a room next door for him to be checked over and apart from a few intermittent cries, we couldn’t hear much from him.

“Here the anaesthetist played his major role; when he could see the anxiety on my face, he continually looked me in the eyes and reassured me. He kept popping his head into the room next door and coming back to say Harry was doing okay. Through my streaming tears, the kindness I could see in this man’s eyes through three layers of facial protection is something I won’t ever forget. He kept talking to Josh and I until Harry finally got his act together and was given the ‘OK’ by the paediatrician.

“Another 40 minutes later with Harry now lying happily on my chest, we were congratulated by all the surgery staff and wheeled back to our room. Josh was allowed to stay for another six hours, the midwife brought me tea and toast, and a bite to eat for Josh as he wasn’t allowed to the canteen; an angel in blue scrubs.

“It was then time for Josh to leave and Harry and I to go to the ward alone. I was given my own room at the end of the corridor with my own private bathroom. The aftercare here from the three shift midwives and postnatal team was warm, comforting and despite having to fully PPE up before even opening my door, was attentive beyond belief.

“Living in Greece for the last ten years without an NHS and without any real need for medical care, it’s something that – even throughout all this year’s media – hasn’t really been at the forefront of my mind. But now back in the UK and after that week’s events, then all the aftercare phone calls we’ve received from midwives and consultants, I’ve never been more grateful for the NHS.

“I wish I could thank them all again for making sure our newest member of the family arrived safely. Harry is currently breastfeeding like a champ, hopefully being pumped full of my Covid-19 antibodies and I’ll take that as a victory!”

Harry is pictured above with mum, Laura, and at the top of the page with his big brother, Jack.